How Gas Sensors Stay Accurate: Zero Calibration vs. Span Point Adjustment

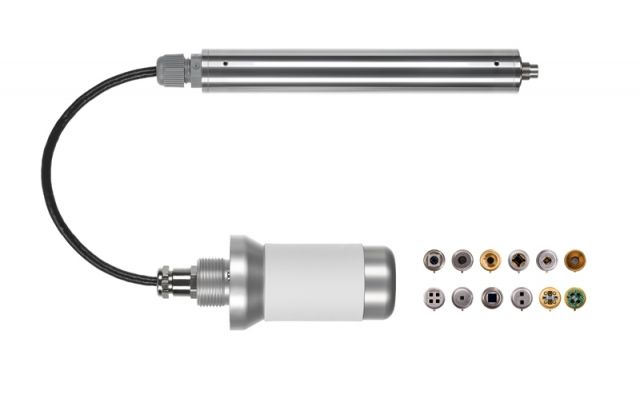

NDIR gas sensors (non-dispersive infrared sensors) detect specific gases in the air. For them to work as accurately as possible, they need to occasionally undergo zero calibration and span point adjustment.

What is Zero Calibration?

Zero calibration gives the sensor a starting point. It defines what the sensor displays when there’s no target gas present. During this process, the sensor is shown none of the specific gas it is looking for, and told that the level it sees is zero. This helps make sure the sensor doesn't give a false reading when no gas is present. However, over time, even the best NDIR sensor will experience drift in its baseline, leading it to report a tiny variation from the actual concentration of gas present. The sensor is not broken - it can “see” as well as it always could. It just needs to be reminded where to start.

Why Zero Calibration Matters?

If a sensor doesn’t know where zero is, its readings can be inaccurate, even if the span point adjustment is well done. A good zero setting is especially important when measuring quite low levels of gas, where a small error can make a big difference.

What is Span Point Adjustment?

Span point adjustment is similar but different. Span point adjustment is how we teach the sensor to give accurate readings when it does see gas. We show the sensor a sample of air with a known amount of the target gas in it, for example, 5000 ppm. We tell the sensor that the amount it is seeing is exactly 5000 ppm. Later, if for example it sees half that amount, it will more accurately register the level as 2500 ppm. This helps the sensor measure gas levels correctly. Calibration can be simple (with just one known value) or more detailed, done with multiple levels of target gas, in order to create an even more accurate scale.

What are Zero Gas and Span Gas?

Zero gas is used for zero calibration: it is clean and has no target gas in it. The sensor looks at this gas and understands its baseline, no-gas setting. Span gas is used for span point adjustment: it contains a known amount of the target gas. This helps train the sensor to measure accurately. It is worth noting that a user should perform a zero calibration right before any span point adjustment is carried out.

Zero Calibration and Span Point Adjustment: How Often Should They Be Done?

There is no one answer to this, because sensors are used for many different things. It depends on the sensor, what it is used for, and the environment it is in. One person’s sensor may be interested in seeing tiny shifts in gas levels, while another’s might only care about very large leaps. Some are used in tough environments and need more help to stay accurate. A typical frequency is once a year for span point adjustment, and once a month for zero calibration - but one size does not fit all. For example, in specific applications such as incubator monitoring, repeated sterilizations will also increase the frequency with which sensors should undergo zero calibration.

What is a "Clean Air" Calibration?

Another type of calibration also exists, known as “clean air” calibration. This works by telling the sensor that the air around it contains none (or a

very low, known amount) of the gas you're trying to measure. That has the benefit of being the less expensive option. When undertaking this process, it is important for the user to surround the sensor with gas that is as clean as possible. For CO₂, for example, this means staying away from cars or people. The sensor must stay in this clean air spot and have time to warm up and stabilize.

You are invited to contact Micro-Hybrid at any time to discuss any of your Micro-Hybrid products and find out what schedule could be ideal for you. Knowing the difference between these two types of adjustments can help your sensor operate as accurately as possible for as long as possible.

Global presence. Local expertise.

With our international Sales and Application Centers, we are close to our customers - wherever they are.

From first contact to technical consultation and after-sales support, our local teams ensure fast response times, in-depth application know-how, and the best service throughout the entire sales process.

Micro-Hybrid Electronic GmbH

Heinrich-Hertz-Str. 8

07629 Hermsdorf | Germany

T +49 36601 592-0

contact@microhybrid.com

Micro-Hybrid Electronic, Inc.

Tech Park Arizona

9030 S. Rita Road,

Suite 122, Tucson, AZ 85747

Qingdao Micro-Hybrid

Electronic Technology CO., Ltd.

92 Chunyang Road, Building 29

Room 1505, Chengyang District