LTCC multilayer ceramic

Electronic circuits are often exposed to particular stresses. LTCC multilayer ceramic technology offers unique solutions for demanding applications in harsh environments.

Micro-Hybrid offers the complete spectrum for the development and production of extremely reliable and miniaturized circuits, from electronic design to the manufacture of LTCC substrates and assembly.

Contact our application experts

What is LTCC?

LTCC stands for Low Temperature Co-Fired Ceramic and refers to a process for the production of ceramic multilayer circuits. By printing the individual ceramic layers, conductive paths, resistors and capacitive and inductive functionalities can be created. The ceramic carriers are pressed and sintered to produce multilayer circuits.

LTCC offers numerous advantages such as high packing density, excellent thermal stability and good electrical insulation. It is therefore ideal for applications in aerospace, high-frequency technology or communication technology.

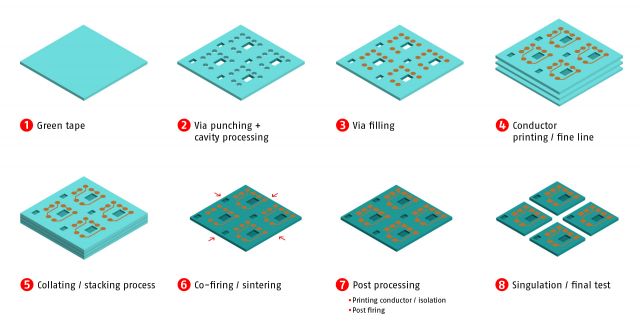

How are LTCC modules manufactured?

We use prefabricated green foils for the production of LTCC. Depending on the specified design, holes are punched at predetermined positions and filled with a metal paste. These so-called vias form the vertical contact in the multilayer structure. The metal pastes are then applied to the green film using a screen printing process and form the planar electrical conductors.

After the metal structures have been applied, the green films are pressed together in a predetermined sequence and sintered at 850 °C - 900 °C. Sensitive structures and surface components can also be applied. The LTCC substrates are then separated and tested for functionality.

- Mechanical processing: milling, punching, laser or water jet cutting possible

- Testing methods: AOI, optical measuring machine or surface scanner

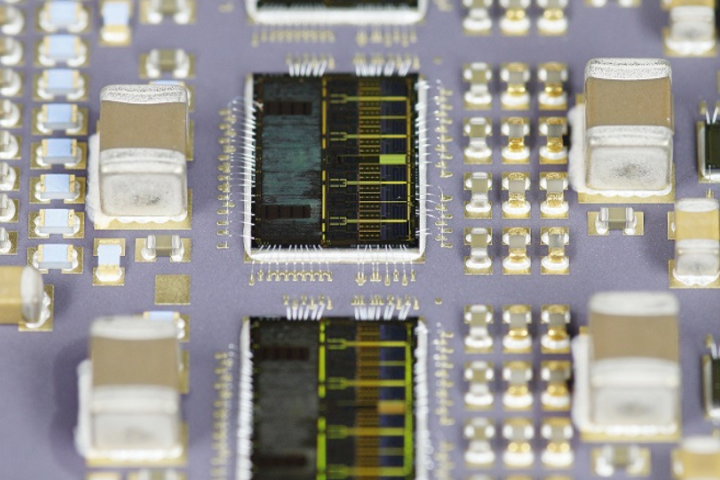

Typical structure of an LTCC circuit

We deliberately do not specify any fixed design rules for the structure of a ceramic circuit. Depending on the specific requirements, our development professionals can design the right circuit for our customers.

The basic properties of such electronics are described here.

| Base materials: | DuPont 951 and DuPont 9K7 |

|---|---|

| Paste systems: | Cofire and postfire pasting; gold/silver systems for the respective tape systems |

| Number of layers: | 2 ... 40 |

| Utility size | 6" × 6" unsintered |

When is LTCC the optimum substrate technology for a circuit?

There are special requirements for electronic circuits and components in numerous applications. LTCC is used when the following is required:

The basic properties of such electronics are described here.

- Ideal thermal conductivity in a wide temperature range (-100 °C ... + 200 °C)

- High frequency stability

- Durable hermeticity

- Long-term stability (> 20 years)

- High dielectric strength and mechanical strength

- Resistance to plasma or ion bombardment

- High degree of miniaturization - 3D features such as cavities, stepped bonding planes, channels and membranes

In contrast to conventional circuit carriers such as FR4, LTCC technology can meet precisely these requirements. Typical areas of application include fields such as medical technology, automotive industry, high-frequency technology, space technology or communication technology.

We will be happy to advise you on your development project and the optimal substrate and packaging technologies.

Direct contact to contact persons

Elektronische Mikro Systeme

Dipl. - Ing.

Thomas Bartnitzek

Senior Business Development Manager