Optimizing NDIR Gas Sensing: Matching IR Emitters and Pyroelectric Detectors

The performance, accuracy, and reliability of Non-Dispersive Infrared (NDIR) gas sensors depend heavily on how well the infrared (IR) emitter is matched with the pyroelectric detector. In particular, both components must be optimized for the specific gas being measured. This guide explains the principles behind IR emitter and detector pairing, using carbon dioxide (CO₂) monitoring as a case study. It details the process of examining specifications to match these components, and highlights the importance of expert guidance in system design.

Understanding Pyroelectric Detector Basics

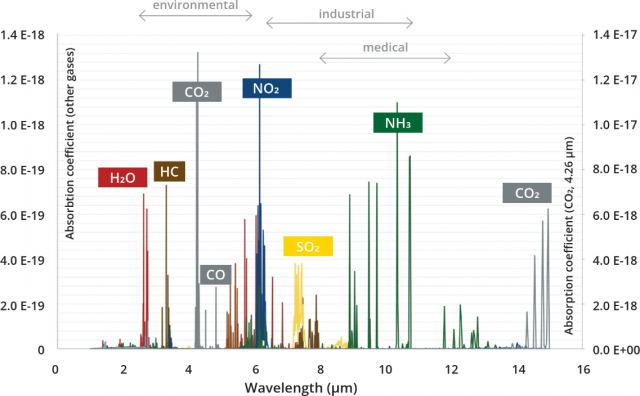

When a pyroelectric sensor is active, an IR source emits infrared light that passes through a chamber filled with gas. The more light the gas absorbs, the less infrared radiation reaches the detector. Each type of gas molecule has a unique "fingerprint" in the IR spectrum, absorbing only specific wavelengths while allowing others to pass. The sensor system must therefore be designed to detect radiation at the strategically chosen wavelengths which the target gas absorbs.

Why Matching Components Is Important

The key challenge is this: not all infrared wavelengths are absorbed equally by all gases. To detect a specific gas effectively, the key requirement is that three things must align:

- We must know the wavelength of IR light that the target gas absorbs.

- The IR emitter must produce radiation at the right wavelength.

- The pyroelectric detector must be sensitive to that same wavelength, typically achieved by an incorporated optical filter.

Case Study: Matching Emitter and Pyroelectric Detector for CO₂ Detection

To explore how to match an IR emitter with a pyroelectric detector, let’s examine one of the most common use cases: detecting CO₂ in air. In order to get a better idea of the matching process, we will look at two components that Micro-Hybrid packages together in a bundle, then look deeper at the specifications to better understand why they are matched together. They are:

The Most Critical Design Principle: Spectral Overlap

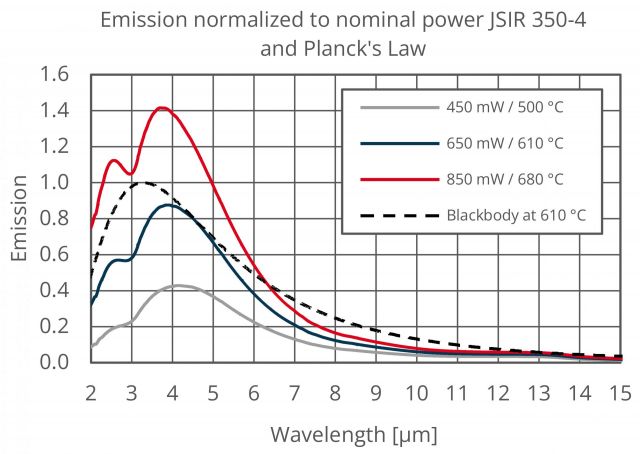

The concept of spectral overlap is central to NDIR sensor performance. The user needs to ensure that the emitter’s output spectrum and the detector’s sensitivity range overlap with the gas’s absorption band. The primary absorption wavelength of CO₂ is ~4.26 µm. So how must our emitter and detector be matched to take this into consideration?

The emitter

Let’s look at one specific spec from the datasheet for our emitter, the JSIR350-4-AL-R-D6.0-N2-A2.

Dieses Modell emittiert Infrarotlicht über einen breiten Bereich von 2–15 µm, der auch eine starke Intensität im für die CO₂-Detektion relevanten Bereich von etwa 4,26 µm umfasst.

The Detector and Why Its Filter Matters

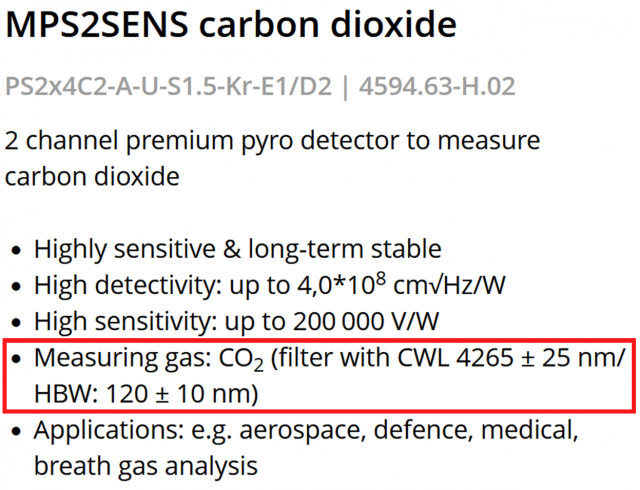

The pyroelectric detector includes an optical bandpass filter, which is the critical component that defines what portion of the IR spectrum reaches the sensor. Here are some key filter specifications for the filter on the PS2x4C2-A-U-S1.5-Kr-E1/D2 detector:

Center Wavelength (CWL) is 4265 ± 25 nm, and Half Bandwidth (HBW) is 120 ± 10 nm. What do those specifications mean?

- CWL: It is important that the detector’s center wavelength (CWL) match well with the gas absorption peak. Because this detector is centered on 4265 ± 25 nm, it is a very good fit for detecting CO₂.

- HBW: Here, we always face a trade-off: a narrower half bandwidth (HBW) means the detector is more selective, which is perfect for isolating a specific gas like CO₂. A wider HBW, on the other hand, allows more IR light in, improving signal strength, but at the cost of specificity. The chosen HBW of 120 nm is a balanced compromise: it is narrow enough to isolate CO₂’s spectral signature, but wide enough to allow sufficient IR energy for a measurable signal.

The tolerances, CWL (± 25 nm) and HBW (± 10 nm), ensure that real-world components fall within acceptable variation due to manufacturing.

To sum up: this pyroelectric detector is appropriate for detecting CO₂ because the emitter outputs light in the spectrum where CO₂ is best detected. Furthermore, the detector’s filter (with its bandpass filter centered at 4.265 µm) ensures its sensitivity range precisely overlaps with the gas’s absorption band, isolating the CO₂ absorption signal.

When Matching Emitters and Detectors for Other Gases, the Same Principles Apply

Different gases absorb infrared radiation at different wavelengths. Below is a summary of typical absorption bands for some gases that can be sensed with NDIR pyroelectric detectors. Knowing these wavelengths and examining specification sheets is a crucial first step - even if specialized system-level expertise goes beyond basic component matching.

Another Consideration: Multi-Channel Pyroelectric Detectors

In real-world environments, especially where multiple gases are present or environmental conditions vary, a single detector channel may not be sufficient. That’s where multi-channel pyroelectric detectors enter the picture. There are two types of channels. The sensing channel measures radiation at the target gas’s absorption wavelength. The reference channel measures radiation at a nearby wavelength where the target gas does not absorb, helping compensate for background drift, temperature changes, or emitter degradation.

Our detector, the PS2x4C2-A-U-S1.5-Kr-E1/D2 includes one channel optimized for CO₂ at 4.265 µm, and one reference channel to stabilize measurements. Other models may include four or five channels to simultaneously detect multiple gases, as here:

However, every channel must still be matched to the emitter’s spectral output, or signal strength may be insufficient. This can create challenges when matching multi-channel pyroelectric detectors and broad-spectrum emitters, as ensuring sufficient power for all filtered channels requires careful emitter selection and optical design.

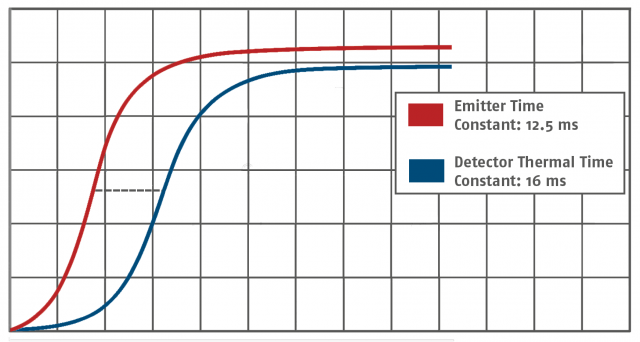

Another Consideration: The Relationship Between the Emitter’s Time Constant and the Detector’s Thermal Time Constant

A pyroelectric detector only produces a signal when its temperature is changing. If the IR radiation it receives remains constant, the detector’s temperature stabilizes and no electrical signal is generated. Therefore, to produce a continuous and detectable signal, the IR source must be modulated, or “pulsed.”

The emitter's time constant determines how quickly it can heat up and cool down in response to these electrical pulses. If the emitter’s time constant is too long relative to the modulation frequency (pulse rate), it won’t have enough time to cool down between pulses or reach peak temperature during a pulse. This results in a weak or distorted signal.

So, what are the specifications for our chosen components?

Emitter Time Constant: 12.5 ms

This is a very good pairing, and well-suited for CO₂ sensing. Here is why:

Matching Time Constants: What You Want

When matching an emitter’s time constant with a pyroelectric detector’s thermal time constant, the most desirable relationship is for the emitter to be slightly faster. This ensures that the detector is exposed to a clean, periodic IR signal with enough thermal variation to generate a strong electrical response. So how can this look?

Emitter slightly faster: This is the desired scenario, and it applies in our case. A faster emitter ensures the detector always receives a sharply modulated IR signal, maximizing signal amplitude and clarity.

Non-ideal pairings are also possible:

Emitter too slow: The emitter becomes the bottleneck. Even a fast detector can’t compensate if the emitter can’t produce sufficient variation in IR radiation.

Detector too slow: The detector can't respond fast enough to the emitter’s pulses, leading to a lagging signal.

Proper matching of time constants improves overall signal quality, response time, and measurement accuracy in NDIR sensing systems.

What Else To Consider?

Matching components for an NDIR system involves several interdependent variables:

- Gas absorption spectrum

- Emitter spectral output

- Filter CWL and HBW

- Relationship between the emitter time constant and the detector thermal time constant

There are also other various considerations, such as differences in ambient conditions, and multi-gas interference. These conditions are extremely varied. This is, in part, why Micro-Hybrid offers pre-configured emitter and pyroelectric detector bundles optimized for specific gases. You are invited to contact Micro-Hybrid and take advantage of our deep expertise in this area. When building an NDIR system, a proper emitter and detector match in the beginning can save months of development time and significantly improve sensor accuracy and reliability.

Global presence. Local expertise.

With our international Sales and Application Centers, we are close to our customers - wherever they are.

From first contact to technical consultation and after-sales support, our local teams ensure fast response times, in-depth application know-how, and the best service throughout the entire sales process.

Micro-Hybrid Electronic GmbH

Heinrich-Hertz-Str. 8

07629 Hermsdorf | Germany

T +49 36601 592-0

contact@microhybrid.com

Micro-Hybrid Electronic, Inc.

Tech Park Arizona

9030 S. Rita Road,

Suite 122, Tucson, AZ 85747

Qingdao Micro-Hybrid

Electronic Technology CO., Ltd.

92 Chunyang Road, Building 29

Room 1505, Chengyang District