Behind the Circuits: Technological Solutions with Structure and Depth

Working Side by Side for Smarter Electronics

Many of their projects begin with a simple sketch on paper – and evolve step by step into custom-built modules through close collaboration. It’s not just about the technology. It’s about partnership: thinking together, deciding together – supported by a team with deep technical expertise.

Their Mission: Electronics That Make a Difference – Tailored to the Application

Andy Wahl studied aerospace engineering and added a business-focused MBA to his technical background – a powerful combination of engineering know-how and strategic thinking. Noah Bleeck started as a dual student in industrial engineering at Micro-Hybrid and knows the company inside out. What unites them: they accompany complex customer projects that demand technical depth and are built to last.

As Andy puts it: “When the technical requirements are clearly defined, and we can turn them into a clean, reliable solution – that’s the kind of project we’re made for.” For Noah, the appeal lies in long-term collaboration, where the result is a well-thought-out module, developed in close partnership.

“Turning a customer’s idea into a well-engineered, production-ready solution – that’s what drives us.”

Andy Wahl

A Solid Technology Base for Demanding Applications

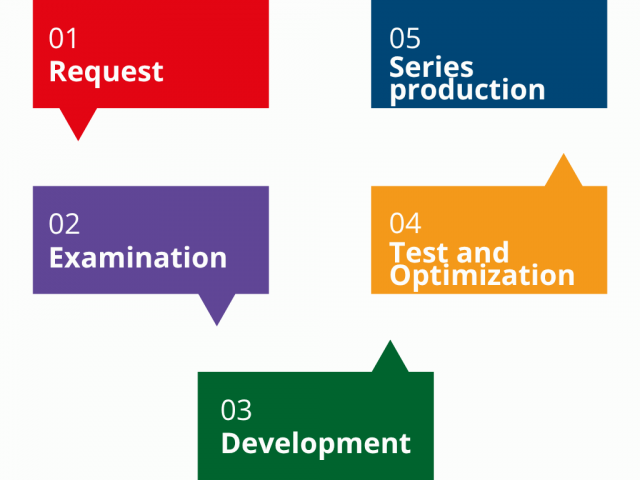

Andy and Noah guide customers through the entire development process – based on a broad in-house technology portfolio: multilayer ceramic circuits in LTCC, thick-film technology, advanced assembly and interconnect techniques (SMD, chip-on-board), and full module integration with housings, encapsulation, and tailored test strategies.

They’re backed by an interdisciplinary team with in-house competence centers for micromechanics and quality assurance. Precision test methods such as X-ray inspection and embedded quality control processes ensure stability and efficient lead times. The goal: not just individual solutions – but seamless systems ready for series production.

Design-In Instead of Off-the-Shelf

Every project is different. Sometimes it’s about improving an existing product, sometimes it starts with just a functional idea. Andy and Noah value this range – because the earlier they’re involved, the more effectively they can shape the design, optimize performance, and prepare for manufacturing.

Whether the challenge is high temperature, pressure, or harsh industrial environments – it’s the combination of material expertise, process knowledge, and testing competence that sets Micro-Hybrid apart. Their specialty begins where standard solutions fall short.

“The more of the process we handle in-house, the more robust the solution – and our customers can feel that.”

Noah Bleeck

Partnership, Not Just Supply

Micro-Hybrid isn’t a conventional supplier – it’s a long-term technology partner. Especially in AEM, Andy and Noah stay closely involved throughout every phase of the project. Whether it’s about obsolescence management, new regulations, or shifting production requirements – they remain the go-to contacts. Their goal is not just delivery, but contribution.

Strong customer relationships – some lasting decades – show that trust, technical competence, and continuity are what truly build value.

Global Mindset, Local Roots

While the AEM focus has been primarily in the DACH region, international collaboration is growing. Technology and development expert Thomas Bartnitzek, with decades of experience, supports the team – especially in the US and China – in further developing their technical capabilities. The mission: real engineering consultancy, not just polished brochures – wherever Micro-Hybrid operates.

And there’s an added strength: Micro-Hybrid’s headquarters in Hermsdorf, Germany. This is where electronics and ceramics have been combined for over 150 years – a unique foundation of know-how that builds trust, across borders.

Next Level: High-Value Modules for Future Markets

From UV curing systems in industrial plants to sensor electronics for semiconductor production – Micro-Hybrid deliberately targets projects with high production depth. When a module passes through all in-house technologies – from thick-film printing to optical inspection – Andy knows: that’s what Micro-Hybrid stands for.

The team sees growth potential in markets like EUV lithography, AI hardware, defense, and high-temperature applications. Complexity? It’s not a barrier – it’s where things get interesting.

Because Micro-Hybrid thrives where others pull back: 180°C, cleanrooms, or environments that leave no room for standard approaches. That’s where electronics are born that truly make a difference.