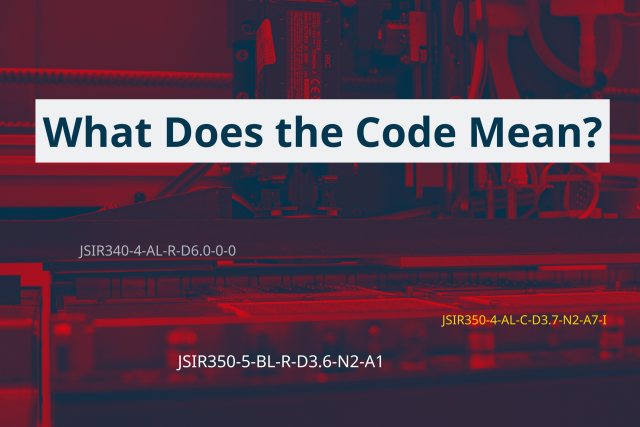

What does the code mean?

The Three Pillars Behind Every Micro-Hybrid IR Emitter

To understand what the code truly conveys, we need to explore the three technological pillars that define every Micro-Hybrid IR emitter.

Pillar 1: Emitter Chip - Performance by Design

At the heart of every IR emitter is the chip, where the fundamental performance characteristics are defined. Radiant intensity, modulation capability, thermal behavior, electrical efficiency, lifetime, and mechanical robustness all originate from this tiny but critical component.

Different applications demand different performance profiles. A high-speed gas analyzer needs strong modulation capabilities, while a safety device prioritizes long-term stability and mechanical robustness. Mobile systems on the other hand, operate with limited power availability and often under variable environmental conditions. Because these mobile systems depend on battery operation or restricted energy sources, emitter efficiency becomes critical. The design focus shifts toward minimizing power consumption while maintaining reliable performance. Because no single chip can optimize all parameters simultaneously, Micro-Hybrid offers multiple chip platforms, each engineered for a defined operating profile.

The product code identifies which chip technology is integrated and what performance philosophy it represents. This ensures the emitter behaves in harmony with the application - rather than forcing the application to adapt to a generic device.

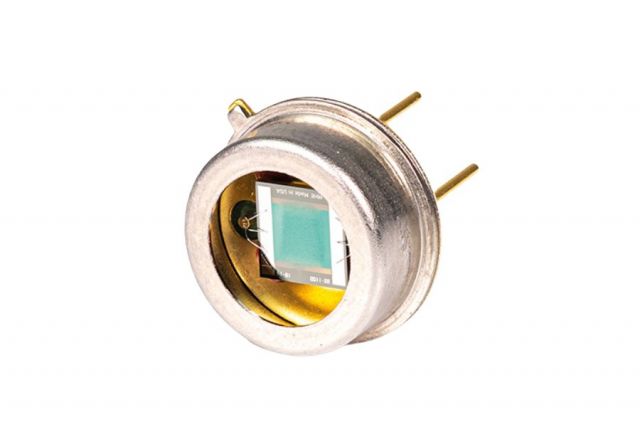

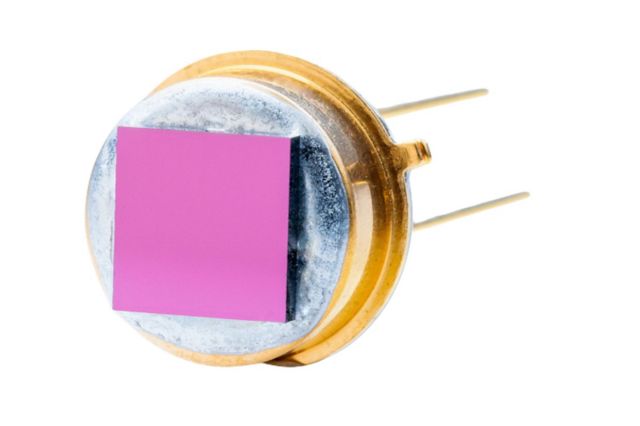

Pillar 2: Optical Window - Protection First, Spectral Fit Second

The optical window is often thought of as a purely spectral element, but its primary role is protection. IR emitters generate extreme heat, often exceeding 600°C, and in harsh atmospheres, the internal structures must be shielded from humidity, corrosive gases, air flow, and contamination.

Only after this protective function is fulfilled do spectral characteristics become relevant. Materials such as sapphire or specialized infrared-transmissive glass are selected not just for their ability to transmit light, but for their ability to balance the demands of the application environment with the wavelengths required.

For example, a system measuring gases below 5.5 µm may use sapphire, while higher-wavelength applications require a different material. The product code encodes these decisions, reflecting both environmental robustness and spectral compatibility. The window is thus not simply an optical element; it is a core part of the emitter’s environmental strategy.

Pillar 3: Hermetic Sealing and Internal Atmosphere - Stability Over Time

IR emitters rarely operate in laboratory conditions. They are deployed in industrial process monitoring, gas safety systems, combustion analysis, and portable detection devices - environments that can be harsh and unpredictable. Micro-Hybrid addresses this reality with hermetically sealed designs, which protect the chip, internal bond connections, reflector structures, and other sensitive materials.

Equally important is the controlled internal atmosphere, typically nitrogen, which prevents oxidation and preserves long-term stability. In safety-critical applications, the design also considers thermal containment, ensuring that the emitter cannot act as an ignition source to flammable gases. The product code thus indicates not only whether a device is hermetically sealed but also the level of environmental stability it provides.

Reflector and System Integration

Beyond the chip, window, and sealing, reflector configurations play a crucial role in shaping radiation directionality, optical efficiency, and system integration. In safety-sensitive applications, the combination of reflector and window designs is carefully engineered to provide both optical performance and safe thermal containment. These choices are deliberate system-level decisions, not cosmetic variations.

What the Code Really Represents

The Micro-Hybrid product code does far more than label a device. It encodes the chip platform, window material, sealing concept, reflector configuration, and overall performance philosophy. Each code reflects engineering trade-offs made consciously for specific applications. It is not marketing shorthand - it is a compact description of a complete design strategy.

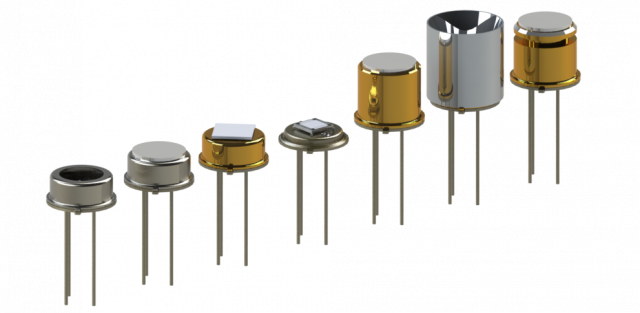

A Structured Technology Platform, Not a Variant List

Micro-Hybrid’s IR emitter portfolio is organized around chip technology platforms, environmental protection levels, optical configurations, and application-focused performance profiles. This structured approach allows engineers to select emitters that fit system requirements, compare technologies transparently, and reduce integration uncertainty. The portfolio mirrors application realities, not abstract configuration logic.

Engineering Depth, Communicated Clearly

Micro-Hybrid communicates the reasoning behind each emitter without revealing confidential design details. Understanding the product code helps customers see why one emitter behaves differently from another, why certain materials are chosen, and why environmental stability and lifetime vary. The code becomes a technical language, reflecting deliberate engineering choices rather than arbitrary differentiation.

Conclusion: What the Code Brings

The product code brings structure, clarity, and engineering intent. Behind every Micro-Hybrid IR emitter stand three defining pillars: the emitter chip design, the optical window and protection concept, and the hermetic sealing with controlled internal atmosphere. Together, these elements define performance, robustness, and lifetime. This is what truly sets the Micro-Hybrid IR emitter portfolio apart - and this is what the code represents.

Global presence. Local expertise.

With our international Sales and Application Centers, we are close to our customers - wherever they are.

From first contact to technical consultation and after-sales support, our local teams ensure fast response times, in-depth application know-how, and the best service throughout the entire sales process.

Micro-Hybrid Electronics, Inc.

Tech Park Arizona

9030 S. Rita Road,

Suite 122, Tucson, AZ 85747

Micro-Hybrid Electronic GmbH

Heinrich-Hertz-Str. 8

07629 Hermsdorf | Germany

T +49 36601 592-0

contact@microhybrid.com

Qingdao Micro-Hybrid

Electronic Technology CO., Ltd.

92 Chunyang Road, Building 29

Room 1505, Chengyang District