Sustainable IR technology - Research project from material selection to manufacturing process

POxIR: Production of polycrystalline oxide IR windows and their integration into an IR sensor

Motivation

The trend towards sustainable solutions to reduce environmental pollution is also playing an increasingly important role in the electronics industry. Therefore, the research consortium Micro-Hybrid Electronic GmbH, Fraunhofer Institute for Ceramic Technologies and Systems IKTS and 5microns GmbH are working on the development of innovative IR windows for process monitoring sensors.

Objective

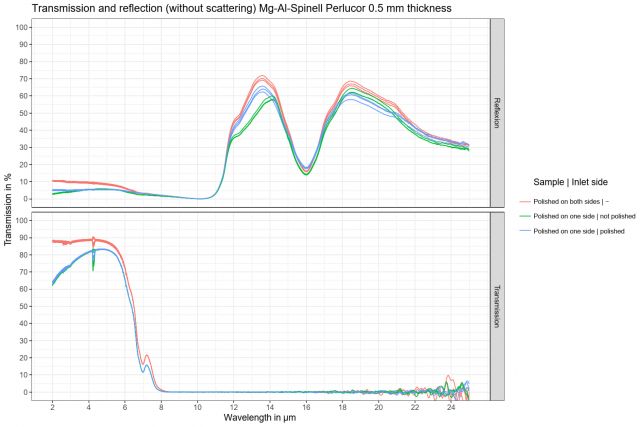

Within the scope of the research project, polycrystalline oxide IR windows are to be produced and integrated into an IR sensor that can withstand harsh environmental conditions. The applications will be in the near infrared (NIR) and mid infrared (MIR) range up to about 9µm to provide an extended wavelength range compared to conventional materials such as sapphire. In the long term, the development has potential for new markets in the area of carbon dioxide CO2, methane CH4, nitrogen oxides NOx and ammonia NH3 measurements. The manufacturing process and material selection should also contribute to CO2 reduction and environmental protection.

Challenge

The key challenge is to find a suitable material that is transparent to infrared radiation and at the same time chemically, mechanically and thermally stable. Current materials are either not stable enough to withstand environmental conditions or require a high level of energy and resources to produce. In addition, there are no established solutions for the integration of transparent ceramics as a filter material in electronic microsystems, and the interaction of this material with coating processes has not yet been explored. Finally, assembly and interconnection solutions must be found to integrate the IR window in series and at low cost.

Solution

- Materials research at the IKTS focuses on oxide ceramic materials that are densified to such an extent that the achieved homogeneity of the grain boundaries makes the ceramic appear transparent. Through successive drying and pressing steps, the base material achieves its transparency with very high purity.

- The project partner 5microns is investigating suitable material combinations and manufacturing processes for the metallic thin films on the transparent ceramics to achieve hermetic sealing. Basic research is being conducted to test how well the layers bond to the ceramic and whether it is possible to fix them permanently.

- Micro-Hybrid is focused on assembling the components in a cost-effective and technically effective manner so that they can later result in a marketable product. The development team is looking for alternative soldering techniques within the assembly and interconnection technology. Micro-Hybrid's extensive market knowledge and experience with customer requirements and industry trends lead the way in defining transmission, durability and geometric design.

The research consortium consists of Micro-Hybrid Electronic GmbH, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS and 5microns GmbH. They received fundings from the European Regional Development Fund (ERDF) of the Free State of Thuringia for the promotion of research, technology and innovation (RTI).

ERDF project code: 2023 VFE 0018

Project period: 10I2023 - 09I2026