Acceleration sensors

Analog acceleration sensors for measuring oscillation and vibrations on the bogie of trains and rail vehicles.

Derailment protection through vibration analysis with electronics in accordance with railroad safety standards EN50155.

Contact our application experts

To the Micro-Hybrid Shop

In our online store you will find a large selection of accelerometers for industrial and rail applications.

– or –

Get in touch

Our application experts will help you find the right sensor for your industrial or mobility application.

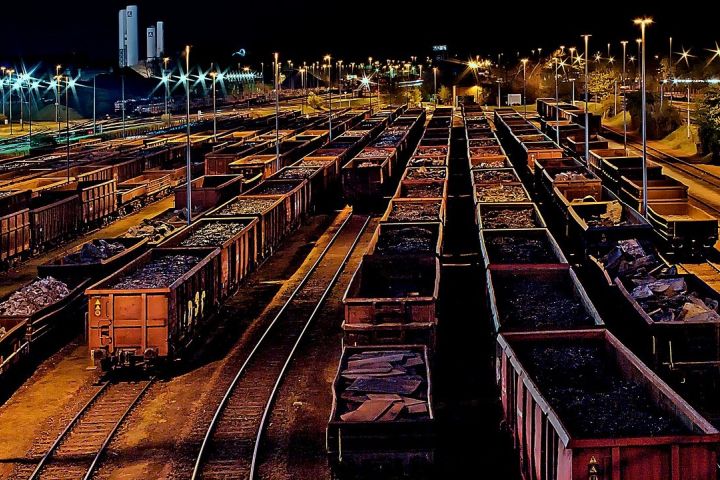

AccTRANS sensors for measuring acceleration and vibration

AccTRANS is a single-axis acceleration sensor. Based on MEMS technology (microelectromechanical system), it records dynamic accelerations. A micromechanical spring-mass system continuously measures the acceleration and converts the measured value into a standard analog current output of 4-20mA. Vibration sensor according to DIN EN 50155 and ready for operation with the power supply directly from the traction unit.

The sensor is designed for applications outside the vehicle or directly on the bogie. The extremely robust housing and special cable withstand harsh environmental conditions such as stone chipping, dust or weather and guarantee high reliability over the entire service life.

Features:

- Measuring range ±4 g*

- Sensitivity 2.0 mA/g*

- Frequency range 0.5-15 Hz*

- Protection class IP68

- Temperature range -40 to +70 °C

*Housing material stainless steel