Wind Turbines and the Impact of Vibration

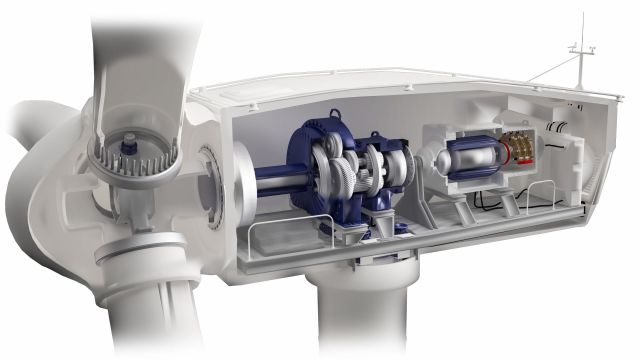

Wind is a reliable and renewable long-term source of energy. The industry has seen explosive growth over the past 25 years and an incalculable rise compared to a century ago. However, the technology needed to deal with the vibrations in massive wind turbines continues to be refined. Operators must precisely monitor and control these vibrations. This is no easy task, as wind turbines are constantly subject to dynamic forces: wind pushing on the blades, rotation of internal gears, and swaying of the tower. This leads to:

- Tower Vibrations:

Movements in the tower put the entire mechanism under stress - vibrations harm the gearbox and generator, leading to heat buildup, increased friction, and eventual failure. - Drive Train Problems:

Imbalances and misalignments in the drive train can severely hurt efficiency and component lifespan. - Rotor Blade Health Issues:

Vibrations can signal structural fatigue or ice buildup on the blades, and excessive vibration can mean more noise, less efficiency, and potential damage.

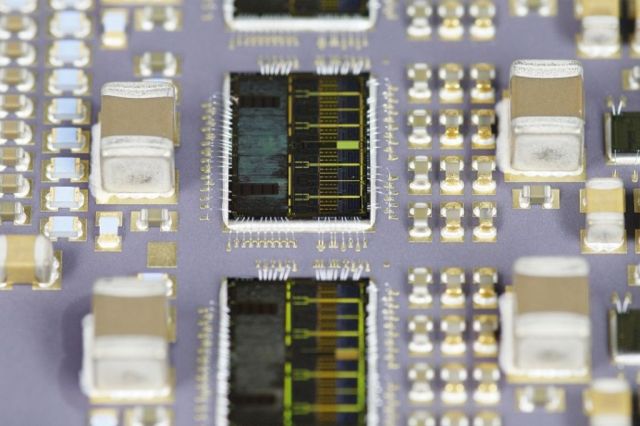

Der Beschleunigungssensor ACC5703-8-SA-U/I von Micro-Hybrid wurde speziell entwickelt, um genau diese Herausforderungen zu meistern.

The High Linearity of the ACC5703-8-SA-U/I

Linearity describes how consistently a measuring device reports reality. Consider a scale that, if you put one kilo on it, reports exactly one kilo. If you put two kilos on it, it reports exactly two kilos, and so

on, as high as the scale allows. Such a scale would be ideal - it would have perfect linearity.

In reality, no scale is perfect. But the ACC5703-8-SA-U/I is designed to be as close as possible. It is very accurate at reporting wind tower vibration, even if the vibrations are extremely small. Although there is a slight “wobble” in readings, the linearity remains highly consistent across the full measurement range. Its linearity is expressed as ±0.15% of the full range: the sensor's reading won’t be off by more than 0.15% of the largest vibration it can measure.

Reliability across Temperature Ranges

The sensors in this product family offer high accuracy and resolution, measuring both static and dynamic accelerations across one, two, or three axes. This extreme sensitivity is key to spotting problems early, allowing for proactive maintenance before small issues become large ones. But because wind turbines operate in extreme environments with large temperature swings, this sensor series is optimized to provide an incredibly stable measurement signal. Accuracy is maintained even at high ambient temperatures. This stability, combined with a sealed die-cast aluminum housing, ensures reliable performance in all weather conditions. This ensures effective monitoring of vibrations in drive trains, rotor blades (for ice detection), and generators (for noise reduction).

Analog vs. Digital Output

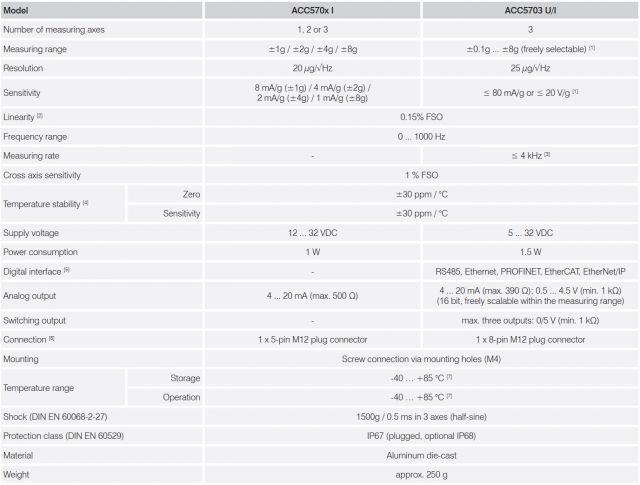

Micro-Hybrid bietet Vibrationssensoren mit unterschiedlichen Datenausgängen an. Ein Vergleich zeigt die Unterschiede:

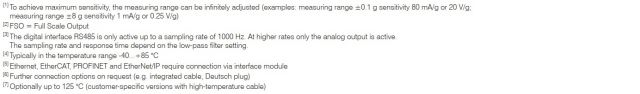

The products described in the middle column offer the same excellent linearity, but they only offer analog output. The ACC5703-8-SA-U/I, on the right, has the advantage of offering digital output, which allows the user to work with data in a highly configurable way.

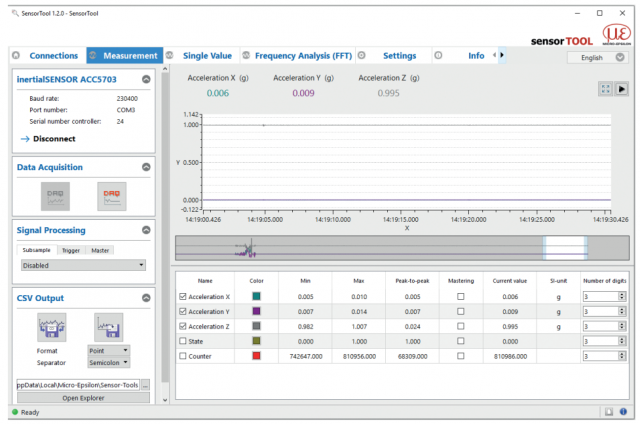

The RS485 Digital Interface and Freely Scalable Analog Outputs

Wind farms stretch over huge areas, necessitating dependable long-distance data transmission. The ACC5703-8-SA-U/I features a digital RS485 interface along with flexible analog outputs. RS485 significantly enhances wind turbine monitoring because it offers extended range: it can send data reliably over distances up to 1200 meters - perfect for sensors spread across a large wind farm. In addition to its impressive range, the RS485 interface can maintain data rates around 100 Kbps at its maximum distance, which is plenty for industrial control and sensor applications in wind turbines.

High Interference Immunity for Increased EMC Requirements

Using a differential signaling method, RS485 effectively cancels out electrical noise from motors, generators, and other industrial machinery. The sensor's strong die-cast aluminum housing further boosts its electromagnetic compatibility (EMC), ensuring accurate data even in noisy electrical environments.

Ideal for Integration into Machines and Systems

The ACC5703-8-SA-U/I is a compact and durable component for precise condition monitoring, designed to fit easily into various machines and systems. By using Micro-Hybrid's ACC5703-8-SA-U/I sensor, wind turbine operators can get crucial insights into the health of their equipment - precise and robust data essential for the reliability of wind turbines. Take advantage of our deep expertise and contact us today to get started.

Global presence. Local expertise.

With our international Sales and Application Centers, we are close to our customers - wherever they are.

From first contact to technical consultation and after-sales support, our local teams ensure fast response times, in-depth application know-how, and the best service throughout the entire sales process.

Micro-Hybrid Electronic GmbH

Heinrich-Hertz-Str. 8

07629 Hermsdorf | Germany

T +49 36601 592-0

contact@microhybrid.com

Micro-Hybrid Electronic, Inc.

Tech Park Arizona

9030 S. Rita Road,

Suite 122, Tucson, AZ 85747

Qingdao Micro-Hybrid

Electronic Technology CO., Ltd.

92 Chunyang Road, Building 29

Room 1505, Chengyang District