Micro-Hybrid Thermopile Detectors: Advantages in Industry and Medicine

Superior DC Response and Stability

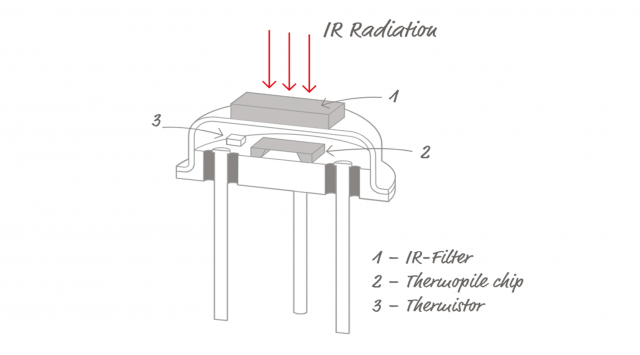

A key benefit of thermopile-based systems is their ability to measure DC (direct current) radiation. Thermopile detectors generate an output voltage proportional to the absolute temperature difference between hot and cold junctions. This enables stable, continuous measurement of steady-state radiation.

In contrast, pyroelectric detectors are AC-coupled devices. Their output is proportional to the rate of change in temperature, which means the IR signal must be modulated (e.g., with a mechanical chopper or pulsed emitter) to produce a usable signal.

The DC response of thermopiles allows for:

- Simplified System Design - No chopper required, reducing system complexity, cost, power consumption, and mechanical points of failure.

- Continuous Monitoring - Essential in industrial process control, continuous emission monitoring, and medical devices such as non-contact thermometers.

Enhanced Performance in Gas Sensing

In NDIR gas analysis critical for industrial safety (e.g., methane, CO, CO₂ detection) and medical diagnostics (e.g., anesthesia monitoring), thermopile detectors combined with Micro-Hybrid IR emitters provide measurable performance benefits:

- Low Power Consumption - Thermopiles are passive, self-generating devices that require no bias. When combined with Micro-Hybrid's energy-efficient IR emitters, complete systems can be designed for low-power, battery-operated devices, ideal for portable medical and remote industrial sensors.

- Signal Integrity - Thermopiles have relatively low output impedance, making them less vulnerable to electrical noise and microphonic effects compared to high-impedance pyroelectric detectors, which require internal impedance conversion circuitry. The result is cleaner, more reliable signals, even in electrically noisy industrial environments.

Robustness in Harsh Environments

Micro-Hybrid thermopile detectors are engineered for durability and long-term stability in demanding conditions:

- High Temperature and Shock Resistance - Certain high-temperature thermopile designs operate reliably in ambient conditions up to 180 °C. This makes them especially suited for industrial process control, including metal and materials processing.

- Hermetic Sealing – Micro-Hybrid thermopile packages can be hermetically sealed, protecting sensitive chip membranes from high humidity, corrosive gases, or elevated partial pressures. This ensures long-term reliability in harsh environments such as process monitoring, leak detection, or emission analysis.

With their stable DC response, low power requirements, and proven robustness, Micro-Hybrid thermopile detectors deliver a highly reliable and cost-effective solution for continuous monitoring in both industrial and medical applications. Explore Micro-Hybrid thermopile detectors and see how they can enhance performance, reduce complexity, and increase reliability in your next industrial or medical application.

Mit ihrer stabilen DC-Reaktion, dem geringen Energiebedarf und ihrer bewährten Robustheit bieten die Thermopile-Detektoren von Micro-Hybrid eine äußerst zuverlässige und wirtschaftliche Lösung für die kontinuierliche Überwachung in Industrie- und Medizinanwendungen.

Entdecken Sie die Micro-Hybrid Thermopile-Detektoren und erfahren Sie, wie sie Leistung steigern, Systeme vereinfachen und die Zuverlässigkeit Ihrer nächsten industriellen oder medizinischen Anwendung erhöhen können.

Global presence. Local expertise.

With our international Sales and Application Centers, we are close to our customers - wherever they are.

From first contact to technical consultation and after-sales support, our local teams ensure fast response times, in-depth application know-how, and the best service throughout the entire sales process.

Micro-Hybrid Electronic, Inc.

Tech Park Arizona

9030 S. Rita Road,

Suite 122, Tucson, AZ 85747

Micro-Hybrid Electronic GmbH

Heinrich-Hertz-Str. 8

07629 Hermsdorf | Germany

T +49 36601 592-0

contact@microhybrid.com

Qingdao Micro-Hybrid

Electronic Technology CO., Ltd.

92 Chunyang Road, Building 29

Room 1505, Chengyang District