Optimizing Power Control for Micro-Hybrid Infrared Emitters

Micro-Hybrid infrared emitters require precise control of electrical input to achieve optimal performance and long-term reliability. This article explores various methods for powering Micro-Hybrid infrared emitters, detailing the advantages and limitations of each approach, and outlines why constant power mode is preferred over constant voltage mode for consistent output and extended lifespan.

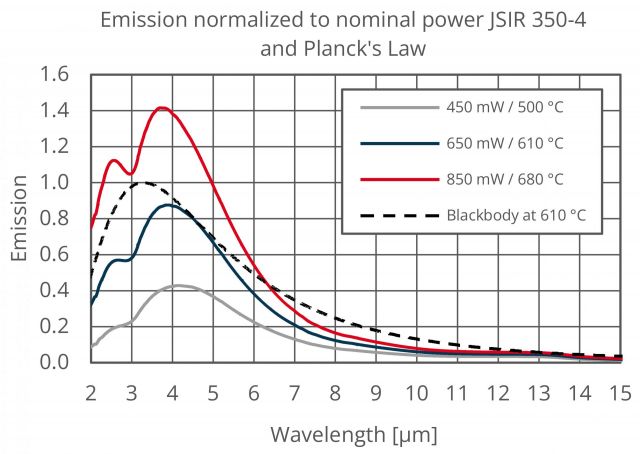

Planck’s Law

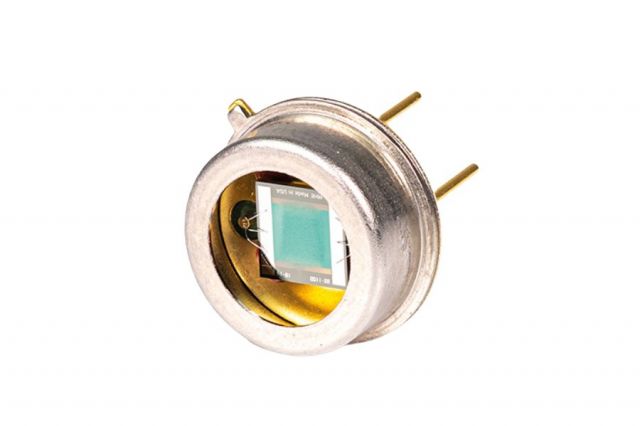

Infrared emitters developed by Micro-Hybrid Electronics rely on an electrically heated membrane as their active area. The optical output of these emitters follows Planck’s Law, which states that the intensity and wavelength of emitted thermal radiation are functions of the membrane temperature.

In other words, the more electrical power is supplied, the higher the temperature and the stronger the radiation - within material and lifetime constraints. However, increasing the temperature also reduces

emitter lifespan. Therefore, it is essential to strike a balance between output performance and durability. With a projected lifetime of over ten years, Micro-Hybrid’s emitters offer ample flexibility for optimization if electrical input is properly managed.

Constant Voltage Mode

Although constant voltage mode is the simplest and most cost-effective method to power an emitter, it is not ideal. Using Ohm’s Law:

...power can be calculated from voltage if the resistance is assumed to be constant. Voltage measurement is straightforward and does not require a current sensing resistor.

However, constant voltage mode presents limitations. Membrane resistance varies with temperature, which alters power delivery despite constant voltage. Variations in resistance from manufacturing tolerances and aging introduce inaccuracies. As a result, this mode is unsuitable for applications requiring high stability or precise control, and it can lead to performance inconsistencies over time.

Constant Power Mode

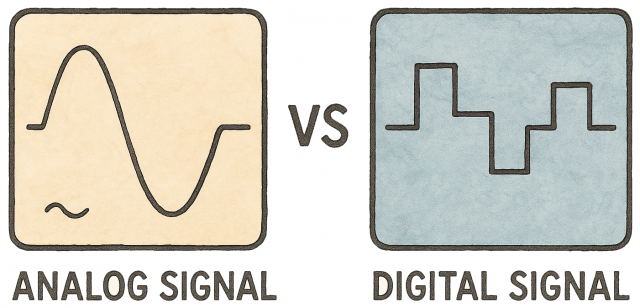

The recommended method for powering your emitter is constant power mode. In this mode, the electrical input is actively regulated to maintain constant power, independent of resistance changes. This can be implemented using either analog or digital control systems:

Analog Implementation:

An analog multiplier can be used to regulate power. However, this method is expensive, prone to linearity errors and electrical noise, and is less scalable in production due to component costs.

Digital Implementation:

A microcontroller can measure both current and voltage and digitally regulate their product. This method is more cost-effective but requires firmware development, bandwidth management, noise handling, and accurate sensor calibration.

Advantages of Constant Power Mode

Using constant power mode ensures long-term optical output stability, even when resistance changes due to temperature, aging, or production variability. This is critical for applications requiring reliable calibration. Emitter lifespan is maximized while maintaining desired output levels.

Application Example: Drought Sensors

In environmental monitoring, particularly drought detection, sensor stability over long periods is critical. Drift in infrared output due to resistance changes can compromise data accuracy. If a sensor inaccurately reports elevated CO₂ levels, it may falsely suggest that plants are actively absorbing CO₂, indicating healthy activity - even when they are actually under water stress.

On the other hand, if the sensor drifts and reports lower CO₂ levels, it might falsely signal severe plant stress and an urgent need for water, even when plants have enough. This can lead to unnecessary irrigation, wasting water and energy, and potentially harming plants through overwatering.

Conclusion

While simpler methods like constant voltage mode may be appealing due to lower cost, they fall short in providing the stability and precision required for long-term, high-reliability applica-tions. Constant power mode offers:

- Superior stability

- Compensation for resistance fluctuations

- Enhanced emitter lifespan

- Better calibration consistency

For more information on ensuring optimal performance across a broad range of environmental and application conditions, visit our website and contact the experts at www.microhybrid.com.