The Importance of Ambient Air Pressure Compensation in NDIR Gas Sensors

Accurate gas detection is critical in applications where safety, regulatory compliance, or process control are at stake. While factors like calibration, temperature stability, and cross-sensitivity are often highlighted, ambient air pressure is frequently overlooked. Yet, without pressure compensation, even small changes in pressure can cause significant measurement errors.

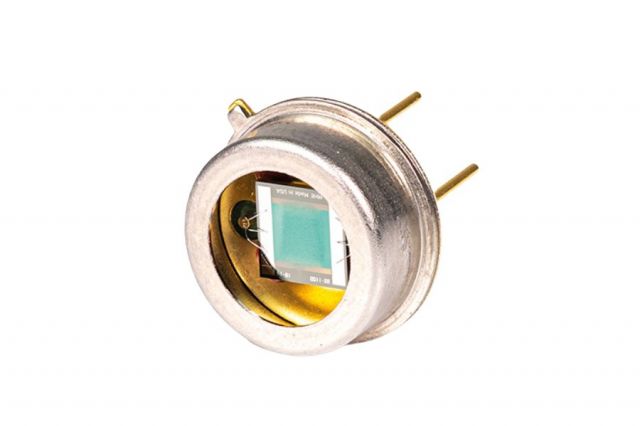

Many non-dispersive infrared (NDIR) gas sensors do not include automatic pressure compensation, shifting the responsibility to end users and increasing the risk of inaccurate data. This document explains why ambient pressure compensation is essential for reliable gas measurement. It also exa-mines how sensors with built-in pressure compensation - such as those from Micro-Hybrid - maintain accuracy under changing environmental conditions. Finally, we compare Micro-Hybrid’s solution with other leading manufacturers that sometimes omit this feature, and quantify the risks of uncorrected deviations.

Why Air Pressure Matters in NDIR Gas Sensing

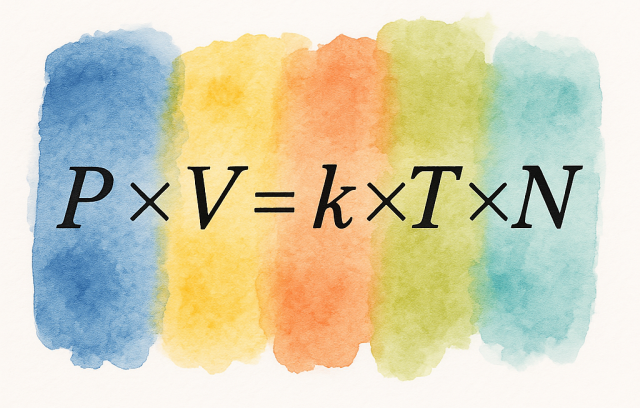

NDIR sensors determine gas concentration based on the number of gas molecules in a fixed volume. According to the ideal gas law:

As ambient pressure decreases, the number of molecules in a given volume decreases. This leads to reduced infrared absorption, which results in an NDIR gas sensor underreporting gas concentrations. Conversely, increased ambient pressure causes overreporting.

How Ambient Air Pressure Affects Non-Compensated Measurements

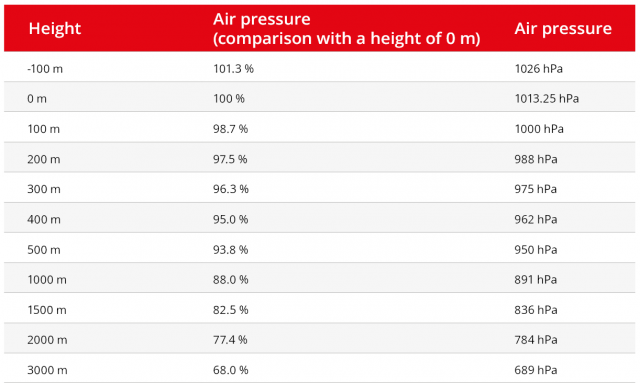

First and most crucially, ambient air pressure varies greatly with elevation. Consider this table:

These variations are significant and must not be overlooked. To put these numbers into context, the highest European capital by elevation, Andorra la Vella, Andorra, is 1023 meters above sea level. By contrast, parts of Amsterdam, Netherlands lie below sea level. Even small changes in elevation at the installation site can influence sensor readings.

As a rule of thumb, air pressure drops by roughly 1 hPa for every 8 meters of elevation gain, up to about 100 meters, though the rate slows at higher altitudes. Some leading manufacturers pre-calibrate their sensors for a fixed reference pressure, often assu-ming standard sea-level conditions, about 1013 hPa. Without an integrated pressure compensation component, the responsibility falls on the end user to supply this data, often leading to a decrease inmeasurement accuracy. altitude with improper manual adjustment. For example, the city of Chengdu sits at an average elevation of 499 meters, where atmospheric pressure is typically around 950 hPa. Imagine an NDIR gas sensor installed in an incubator there, but still calibrated for sea-level pressure (1013 hPa).

The resulting measurement error is estimated as follows:

(1013 hPa - 950 hPa) × 0.0073 Vol.-%/hPa = 0.459 Vol.-%

That level of deviation is far beyond acceptable tolerances for precision gas monitoring, which often demand accuracy within ±0.2 Vol.-%.

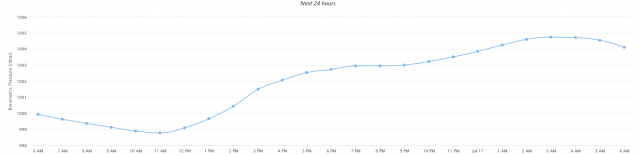

Pressure also Fluctuates with Local Weather

Even at a fixed location, ambient air pressure varies. Let’s consider the air pressure variation in this forecast for Beijing on July 16, 2025:

Daily Variation in Beijing (July 16, 2025)

- Minimum pressure: 998.7 hPa

- Maximum pressure: 1004.75 hPa

- Difference: 6.05 hPa

For a 5 Vol.-% target, the error would be:

6.05 hPa × 0.0073 Vol.-%/hPa = 0.044 Vol.-%

Even without changing location, the gas reading could deviate by over 0.04 Vol.-% in a single day, exceeding tolerance for many applications.

A Two-Week Variation in Beijing, July 2025

- Minimum: 994.7 hPa (July 15, 11:00)

- Maximum: 1011.62 hPa (July 17, 03:00)

- Range: 16.92 hPa

This is equivalent to an error of 16.92 × 0.0073 = 0.1235 Vol.-% and is not appropriate for critical use ca-ses. These routine fluctuations show that when NDIR gas sensors that are not automatically calibrated for ambient pressure they can easily drift out of spec, even without changes in altitude.

How much accuracy is lost?

To stay within a ±0.2 Vol.-% accuracy window at 5 Vol.-%, the maximum allowable pressure deviation is:

0.2 / 0.0073 ≈ 27 hPa deviation

This threshold is easily exceeded in daily weather cycles, particularly during storms, or when reloca-ting equipment between sites. Even moderate pressure changes can cause readings to fall outside specifications.

Every Micro-Hybrid Sensor Compensates for Ambient Air Pressure

All Micro-Hybrid NDIR sensors feature integrated pressure sensors, enabling real-time compensation without user intervention. Key benefits include accurate readings regardless of installation altitude, automatic correction for daily and seasonal pressure fluctuations, with no manual pressure entry or recalibration needed, and consistent readings across multiple locations and environments.

This built-in compensation dramatically reduces the risk of data drift and greatly boosts regulatory compliance and measurement trustworthiness. Ambient air pressure is a major source of error in NDIR gas sensing, yet it’s frequently ignored. Manufacturers that omit integrated compensation shift the burden to end users, often compromising accuracy. Micro-Hybrid’s sensors solve this problem at the source, using built-in pressure sensors to maintain accuracy automatically, regardless of elevation or weather. This is essential for reliable gas monitoring. Consult the experts at Micro-Hybrid to ask about the best solution for your application.

Global presence. Local expertise.

With our international Sales and Application Centers, we are close to our customers - wherever they are.

From first contact to technical consultation and after-sales support, our local teams ensure fast response times, in-depth application know-how, and the best service throughout the entire sales process.

Micro-Hybrid Electronic, Inc.

Tech Park Arizona

9030 S. Rita Road,

Suite 122, Tucson, AZ 85747

Micro-Hybrid Electronic GmbH

Heinrich-Hertz-Str. 8

07629 Hermsdorf | Germany

T +49 36601 592-0

contact@microhybrid.com

Qingdao Micro-Hybrid

Electronic Technology CO., Ltd.

92 Chunyang Road, Building 29

Room 1505, Chengyang District